Janssen Pharmaceutica

Janssen continuous manufacturing Mirror 2

The challenge

Helping Janssen integrate continuous manufacturing

Continuous manufacturing gives pharmaceutical organisations industry-leading best practices and processes, reducing cycle time, providing real-time quality assurance and reducing their operating costs.

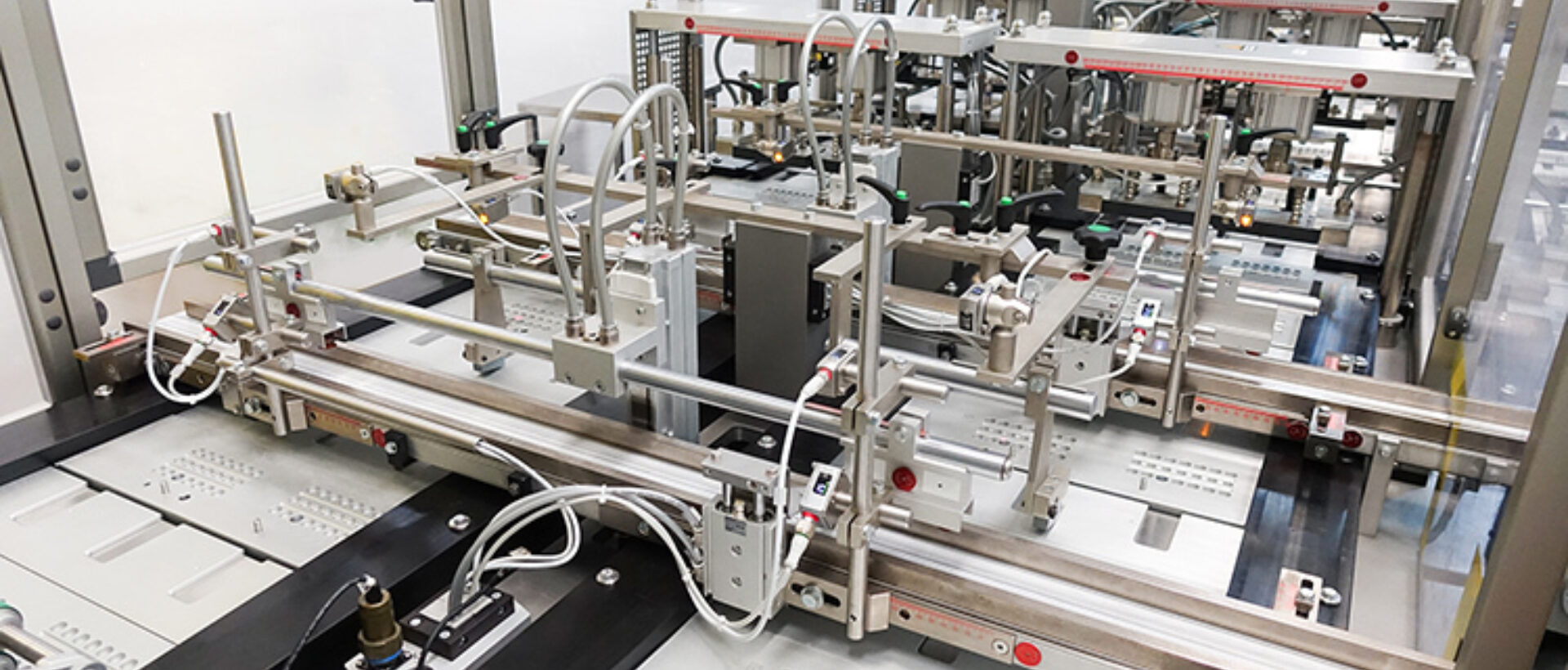

Our client, Janssen Pharmaceutica, was rolling out a programme (called Mirror) to introduce continuous manufacturing at key sites across Europe. At Latina in Italy, Mirror 2 would involve integrating direct compression and roller compaction into the existing vertical facility.

The role we're playing

Janssen asked our Pulse Consult life sciences construction specialists to support them on this project, following our successful collaboration on the Mirror 1 line in Beerse, Belgium. We’ve provided early stage estimate validation, as well as an integrated schedule for the entire five-year project, which we’re managing right through to completion.

Continuous manufacturing was new to the Latina site, so it involved complex, lengthy commissioning and qualification stages. We incorporated these into our full project schedule right from the outset, giving the client certainty around when their new manufacturing capacity would be ready, online and generating revenue.

We’re also providing detailed cost forecasting, progress and cost reporting, schedule risk assessments, scope change management, cashflow tracking, savings capture and payment application reviews.

The results

When it’s finished, the facility will give the team at Latina fully integrated continuous manufacturing, from weighing right through to tabletting. This will include direct compression and roller compaction, automated clean-in-place (CIP) and sterilisation-in-place (SIP) systems, and the ability to feed in pre-blends, providing greater control over individual active pharmaceutical ingredients API.

The team will have cutting-edge control software and integration, including automation and human-machine interfaces (HMI). The system will also include process analytical technology (PAT), so they can enhance their processes in real time. Across the site, updates and adaptations to buildings and utilities will make sure all the new capabilities fit in seamlessly.

We’re proud to be supporting Janssen with this business-critical project, delivering a cutting-edge facility that will secure their key solids product pipeline for the immediate future and give them vital bridging capacity until future manufacturing lines come on stream.

Construction consultancy services provided on this project

- Construction planning & project controls

- Planning & scheduling

- Risk management

- Estimation & costing

The stats

3 new

manufacturing shifts per day

6k

manufacturing hours created per year

Services provided for this project

Arrange a meeting

Like to talk about construction consultancy for your next project?

Get in touch with Kevin Jones today.